Precision Plastic Molding: A Revolution in Manufacturing for Various Industries

Introduction

When it comes to the intricate and precise manufacturing processes required for various industries, nothing can compare to the capabilities of precision plastic molding. At Deep Mould, our commitment to innovation and excellence has led us to become a leading provider of high-quality plastic molds and fabrication services. In this article, we will explore the transformative potential of precision plastic molding, its advanced techniques, wide range of materials, and numerous applications that have revolutionized modern manufacturing processes.

The Evolution of Precision Plastic Molding

Precision plastic molding has come a long way since its inception. With advancements in technology and materials, businesses can now achieve unparalleled levels of accuracy in their manufacturing processes. At Deep Mould, we have closely followed the industry trends and invested in state-of-the-art machinery, enabling us to cater to the growing demands for precision moldings across multiple sectors.

Techniques

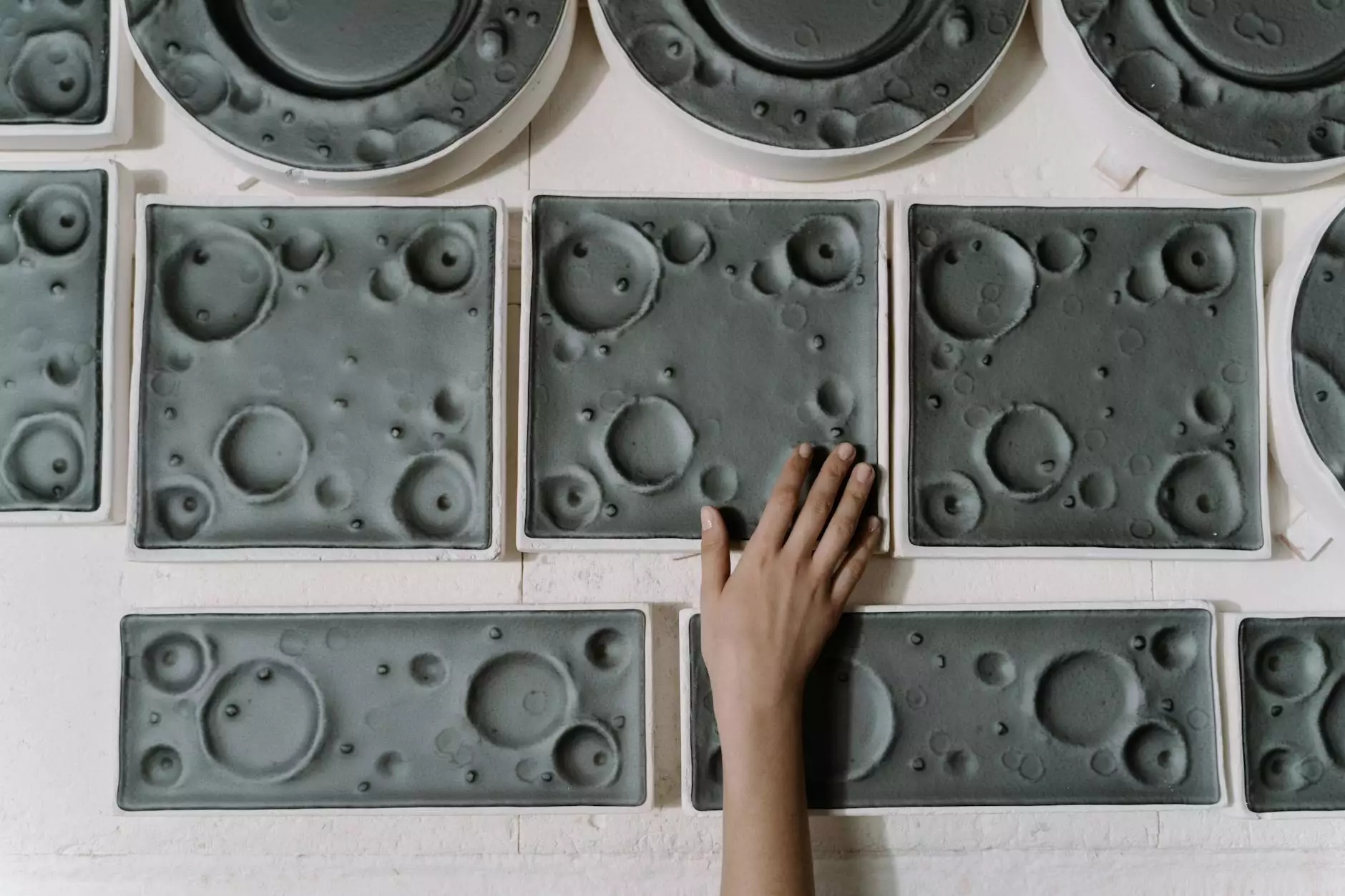

The precision achievable in plastic molding is a result of the advanced techniques employed during the process. Injection molding, for example, allows for the creation of highly intricate and complex components with minimal wastage. This technique involves injecting molten plastic into a mold, which takes the desired shape after cooling. Other techniques such as blow molding, rotational molding, and compression molding contribute to the versatility of precision plastic molding.

Materials

One of the key advantages of precision plastic molding is the vast array of materials that can be used. From traditional thermoplastics like polyethylene and polypropylene to high-performance polymers such as PEEK and ULTEM, businesses have access to a wide range of materials to meet their specific application requirements. The ability to choose from various materials ensures that the final product not only meets functional expectations but also delivers exceptional durability and longevity.

Applications

Precision plastic molding finds applications across numerous industries, contributing to their success and growth. In the automotive sector, precision molded plastic components are widely used in interiors, exteriors, and under-the-hood applications. The medical industry greatly benefits from precision plastic molding in the production of medical devices and equipment, providing cost-effective solutions without compromising on quality. Industries such as electronics, aerospace, and consumer goods also rely heavily on precision plastic molding to enhance their product performance and functionality.

The Deep Mould Advantage

Deep Mould is a trusted partner for businesses seeking precision plastic molding solutions. Our commitment to excellence, cutting-edge technology, and expertise in the field set us apart from the competition. As metal fabricators and pioneers in precision plastic molding, we strive to provide our clients with the utmost quality and efficiency in their manufacturing processes.

Quality Control Measures

At Deep Mould, we understand the significance of stringent quality control measures in achieving precision plastic molding. Our team of skilled professionals ensures that every component produced adheres to the highest quality standards. With advanced inspection and testing methods, we guarantee consistency throughout the process and deliver products that exceed customer expectations.

Efficiency and Tolerances

Efficiency is a critical aspect of precision plastic molding. At Deep Mould, we have optimized our manufacturing processes to ensure maximum efficiency, resulting in reduced production times and costs for our clients. Moreover, our expertise in achieving tight tolerances helps businesses meet the most demanding design specifications, giving them a competitive edge in their respective industries.

The Benefits of Precision Plastic Molding

The benefits of precision plastic molding are numerous and extend far beyond improved manufacturing processes. By choosing Deep Mould as your trusted partner, businesses can experience reduced production costs, enhanced product performance, faster time-to-market, and improved overall efficiency. Our attention to detail, commitment to customer satisfaction, and ability to deliver exceptional results make us the go-to option for precision plastic molding needs.

Conclusion

Precision plastic molding has revolutionized the manufacturing processes across numerous industries, providing businesses with cost-effective solutions, improved product quality, and enhanced functionality. Deep Mould, as a leading provider of high-quality plastic molds and fabrication services, is committed to delivering exceptional results through advanced techniques, a wide range of materials, and a keen focus on quality control. Choose Deep Mould for all your precision plastic molding needs and experience the transformative power of our innovative solutions.