The Ultimate Guide to Label Applicator Machines

Introduction

The demand for efficient, precise labeling solutions has never been higher in the fast-paced world of modern business. One of the key players in this market is the label applicator machine, a revolutionary device designed to streamline the labeling process, enhancing both productivity and accuracy. In this extensive guide, we will delve deep into what label applicator machines are, their functions, applications, and why your business—especially if you're involved in printing services, electronics, or computers—should consider incorporating them into your operations.

What is a Label Applicator Machine?

A label applicator machine is a device used in various industries to apply labels onto products, packaging, or containers. These machines can handle various types of labels and are crucial for ensuring that products are correctly identified and comply with regulatory requirements. They come in various forms, from manual handheld devices to fully automated high-speed systems.

Types of Label Applicator Machines

There are several different types of label applicator machines, each tailored to meet specific needs:

- Automatic Label Applicators: These machines automatically dispense and apply labels to products at high speeds, making them ideal for large-scale operations.

- Semi-Automatic Label Applicators: These require some manual input but offer greater efficiency than fully manual options.

- Handheld Label Applicators: Portable and easy to use, these machines are suitable for small businesses or low-volume applications.

- Print and Apply Systems: These integrate printing and labeling into one system, allowing businesses to print variable information directly onto labels and apply them simultaneously.

How Do Label Applicator Machines Work?

Understanding the functionality of a label applicator machine helps businesses make informed decisions when purchasing or integrating such technologies. Here’s a brief overview of how these machines typically operate:

- Label Feed: The machine draws labels from a roll or stack, ensuring they are ready for application.

- Label Positioning: The applicator aligns the label accurately, using sensors and guides to position it precisely.

- Label Application: The labels are applied using various methods, such as pressure-sensitive application or through automation that involves rollers or pneumatic systems.

- Verification: Many machines are equipped with verification systems that ensure labels have been applied correctly before proceeding.

Benefits of Using Label Applicator Machines

Investing in a label applicator machine brings numerous benefits to businesses, including:

- Increased Efficiency: Automated labeling significantly speeds up the packing and shipping process.

- Consistency and Accuracy: Machines apply labels uniformly, reducing the chances of human error.

- Cost-Effective: Over time, these machines reduce labor costs and waste from mislabeling.

- Versatility: Many machines handle various label sizes and shapes, catering to diverse product lines.

- Enhanced Compliance: Ensure products meet regulatory labeling standards, crucial in industries like food and pharmaceuticals.

Applications of Label Applicator Machines

A label applicator machine is utilized across various industries. Here are some common applications:

1. Food and Beverage Industry

In the food and beverage sector, labeling is critical for compliance and marketing. Label applicator machines ensure that products are labeled accurately for ingredient lists, nutritional information, and expiration dates.

2. Pharmaceuticals and Cosmetics

These industries require precise labeling for regulatory compliance. Automatic label applicators are vital in ensuring that medication and cosmetic products have clear, consistent labeling.

3. Manufacturing

In manufacturing, label applicators are used for product identification, tracking, and inventory management, ensuring seamless operations and logistics.

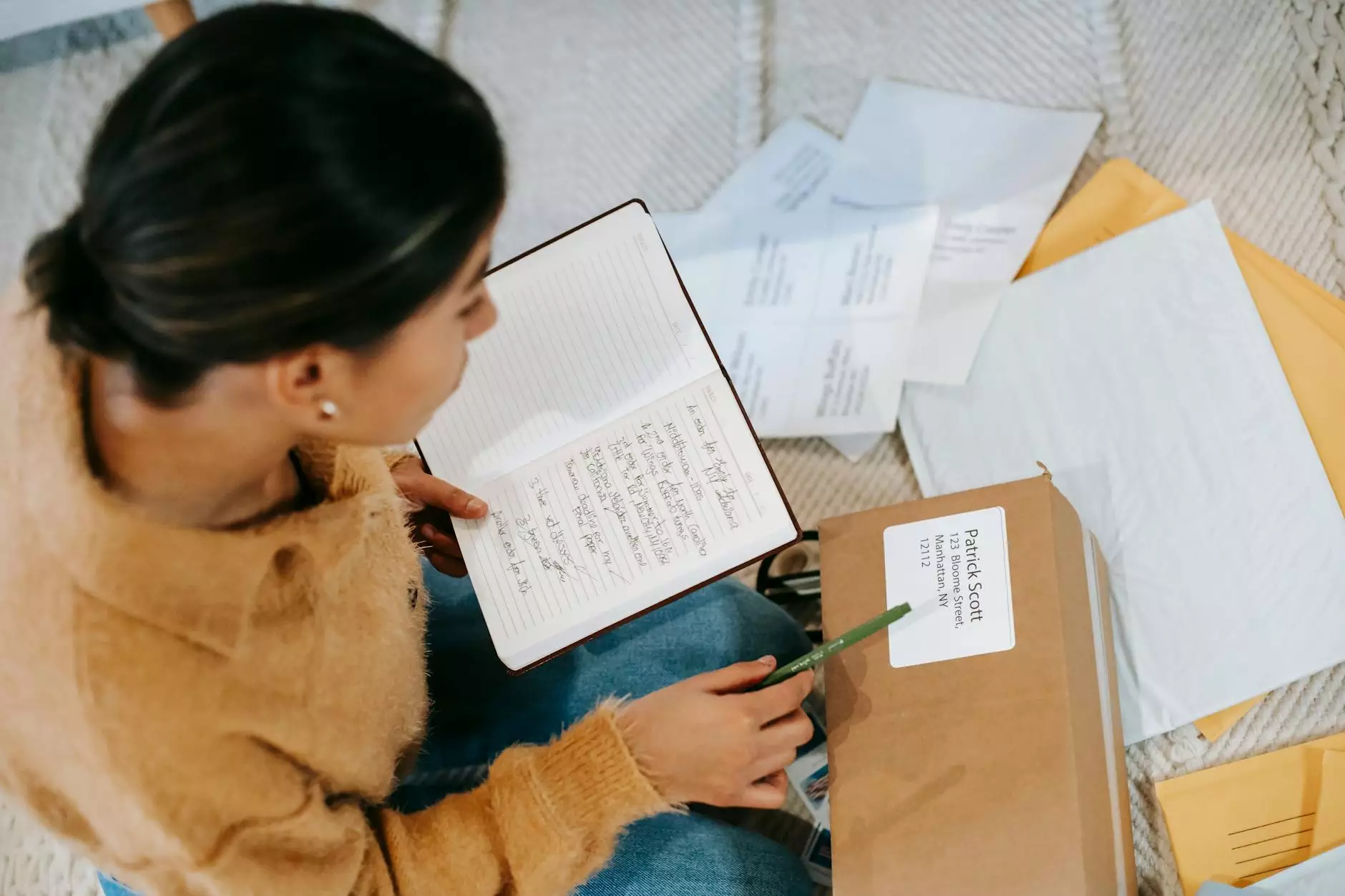

4. E-commerce and Retail

As online shopping grows, efficient labeling is crucial for packing and shipping. E-commerce businesses leverage these machines for efficient logistics.

Choosing the Right Label Applicator Machine

Selecting the appropriate label applicator machine involves several considerations:

- Production Volume: High-volume operations benefit from fully automated systems, while smaller operations may prefer semi-automatic or manual options.

- Label Size and Type: Ensure the machine can accommodate the sizes and materials of labels used in your products.

- Integration Capabilities: The machine should seamlessly integrate with existing production lines and systems.

- Budget: Assessing both the initial investment and ongoing maintenance costs is critical.

- Vendor Support: Look for suppliers, like Omega Brand, that offer excellent after-sales support and service.

Maintaining Your Label Applicator Machine

To ensure longevity and consistent performance, regular maintenance of your label applicator machine is essential. Here are some tips:

- Regular Cleaning: Dust and residue can affect the machine’s functionality. Regularly clean the dispensing mechanism and sensors.

- Inspect Components: Routine inspections can prevent minor issues from becoming major faults.

- Calibrate as Needed: Ensuring the machine is calibrated correctly guarantees accuracy in label application.

- Keep Software Updated: If your machine has software components, ensure they are updated to the latest versions.

Conclusion

The label applicator machine is an invaluable asset that can significantly enhance operational efficiency for any business involved in printing services, electronics, or computers. By investing in this technology, businesses can improve labeling accuracy, compliance, and overall productivity. As industries continue to evolve and grow, the role of such technologies will only become more critical in maintaining a competitive edge.

Discover More with Omega Brand

At Omega Brand, we pride ourselves on being at the forefront of printing services and electronic solutions. With our extensive range of products tailored for the specific needs of our clients, including top-of-the-line label applicator machines, we are committed to providing tools that drive success. Visit us at omegabrand.com to learn more about our offerings and how we can help elevate your business today.