Exploring the Benefits and Applications of Rapid Prototyping Injection Molding

The world of manufacturing and product development is continuously evolving, and one of the most significant advancements is the emergence of rapid prototyping injection molding. This innovative technique has transformed how businesses approach product design and manufacturing, offering unparalleled advantages in terms of speed, efficiency, and cost-effectiveness. In this article, we will delve deep into the intricacies of rapid prototyping injection molding, its benefits, applications, and how it serves as a game-changer for manufacturers, especially for those within the Metal Fabricators industry.

Understanding Rapid Prototyping in Injection Molding

To appreciate the significance of rapid prototyping injection molding, it’s crucial to start with a clear understanding of what it entails. Rapid prototyping refers to the rapid fabrication of a physical part or assembly using CAD (Computer-Aided Design) software and additive manufacturing techniques. In the context of injection molding, this means creating prototypes quickly and efficiently, allowing companies to test and iterate on designs before moving into full-scale production.

How Rapid Prototyping Injection Molding Works

The process generally involves several key steps:

- Design Creation: The process begins with the creation of a 3D digital model using CAD software.

- Optimization: The design is optimized for manufacturability, ensuring that it can be produced efficiently using injection molding techniques.

- Prototype Production: A prototype is made using a rapid injection molding machine, which allows for the creation of molds quickly.

- Testing and Evaluation: The prototype is tested for functionality, aesthetics, and market fit, allowing for feedback and modifications.

- Final Adjustments: Based on the evaluations, necessary adjustments are made before the final production stage.

Key Advantages of Rapid Prototyping Injection Molding

1. Speed to Market

One of the most significant advantages of rapid prototyping injection molding is the reduction in time to market. Traditional molding techniques can be time-consuming due to the lengthy process of mold creation. Rapid prototyping, on the other hand, allows companies to produce functional prototypes in days rather than weeks. This acceleration not only speeds up product development but also enables businesses to respond more quickly to market demands.

2. Cost-Effectiveness

Another crucial benefit is the ability to reduce costs. Creating molds for traditional injection molding can be extremely expensive, often reaching thousands of dollars. With rapid prototyping injection molding, manufacturers can produce lower volumes of prototypes at a fraction of the cost, allowing for more flexible budgeting and reduced financial risk.

3. Design Flexibility and Iteration

The nature of rapid prototyping encourages design improvement. The speed at which prototypes can be created means that designers can experiment and innovate without the fear of being financially burdened by each iteration. This agility is essential in today's fast-paced markets, allowing for real-time adjustments to meet customer needs and preferences.

4. Enhanced Product Quality

With the ability to test prototypes quickly and efficiently, businesses can ensure that their products meet high-quality standards before they go into full-scale production. This leads to improved final products that better align with customer expectations and industry standards.

Applications of Rapid Prototyping Injection Molding

The applications of rapid prototyping injection molding span a wide array of industries, affirming its versatility and relevance in modern manufacturing.

1. Medical Devices

The medical industry requires high precision and stringent adherence to regulations. Rapid prototyping allows for the creation of medical device prototypes that can be tested and refined quickly, ensuring compliance with safety standards and improving time-to-market for critical products.

2. Automotive Industry

In the automotive sector, the use of rapid prototyping injection molding facilitates the development of components that must meet strict performance specifications. Prototypes can be rapidly manufactured for parts ranging from interior designs to complex engine components, significantly speeding up the design and testing phases.

3. Consumer Electronics

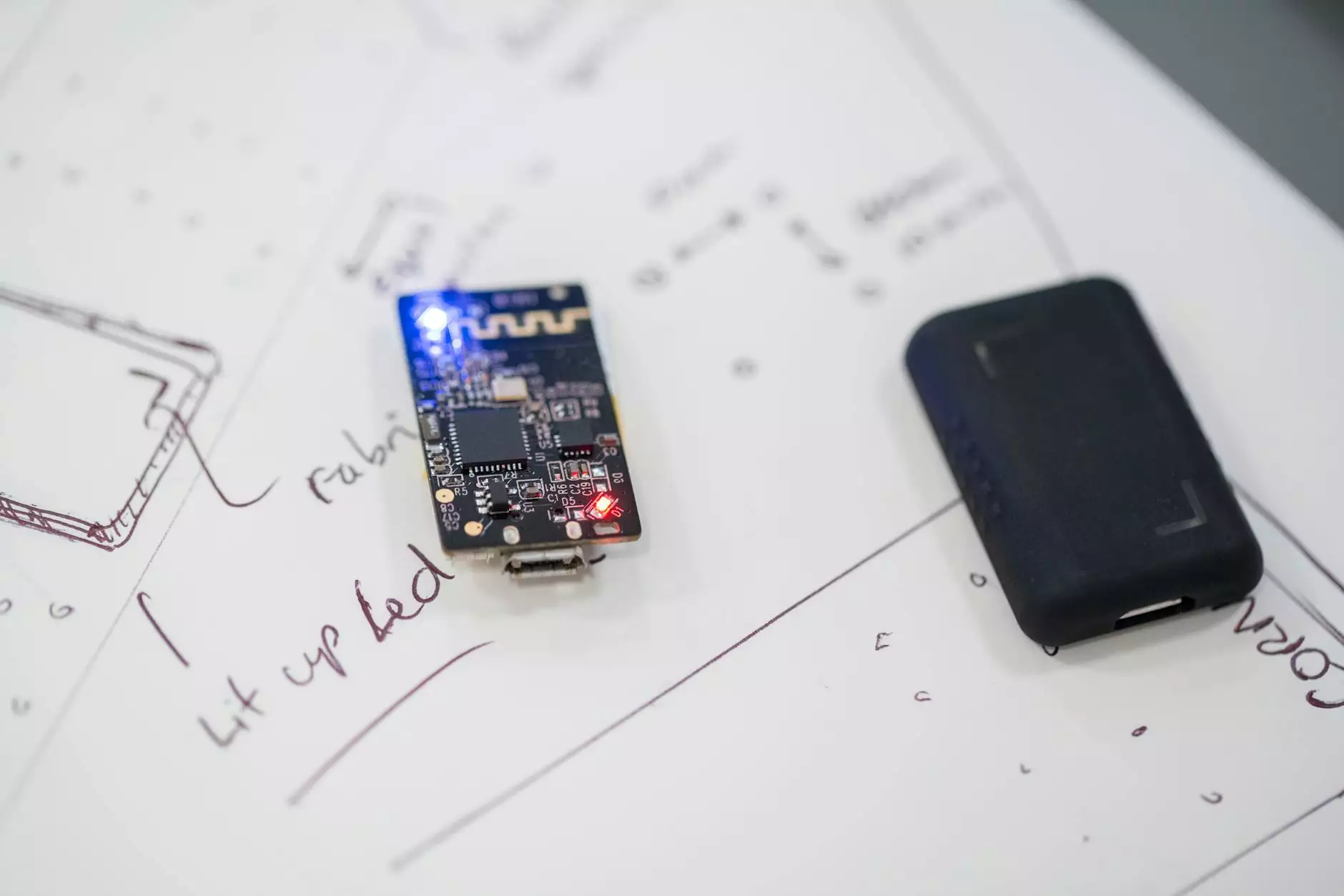

The fast-paced world of consumer electronics benefits greatly from rapid prototyping. Companies can quickly iterate on designs for devices, ensuring they stay competitive in a market that demands innovation and quick releases. From phone casings to internal circuit structures, rapid prototyping is pivotal in the design process.

4. Home Appliances

For manufacturers of home appliances, rapid prototyping provides the ability to create visually appealing prototypes that consumers can interact with. The fast feedback loop allows for enhancements in both functionality and aesthetics, ensuring products meet consumer expectations.

Challenges and Considerations

While the benefits are considerable, there are inherent challenges in implementing rapid prototyping injection molding effectively:

- Material Limitations: The choice of materials for the prototypes can be limiting, as not all materials used in final products can be utilized for rapid prototypes.

- Complex Geometry: Some intricate designs may require advanced customization of the molds, which can complicate the rapid prototyping process.

- Initial Investment: The upfront cost of purchasing rapid prototyping equipment can be daunting for small businesses, although the long-term savings often justify the expense.

The Future of Rapid Prototyping Injection Molding

As technology continues to advance, the future of rapid prototyping injection molding looks increasingly promising. The integration of newer materials such as bio-resins and advanced composites will expand the potential applications and improve the sustainability of the manufacturing process. Additionally, advancements in automation and machine learning could further enhance efficiencies, improve product designs, and reduce costs.

Conclusion

In conclusion, rapid prototyping injection molding presents a transformative opportunity for businesses, especially in the Metal Fabricators industry. With its ability to drastically reduce time to market, lower costs, and improve product quality, this technique stands out as a critical tool in modern manufacturing. By embracing this approach, companies can not only innovate at a faster rate but also enhance their competitive advantage in an ever-evolving market landscape.

For businesses considering the adoption of rapid prototyping injection molding, partnering with experienced manufacturers such as DeepMould.net can provide the necessary expertise and resources to make the transition smooth and successful.